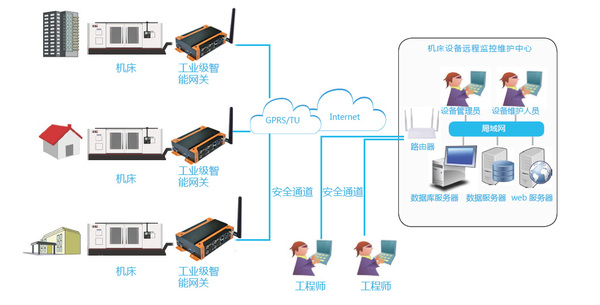

Application Scheme of GEA-8401 in Machine Tool IoT Monitoring

At present, there is a demand for machine tool status diagnosis in the CNC machine tool industry. It is necessary to transmit the running status and alarm information of the machine tool to the central server remotely through wireless communication terminals in a timely manner. The server will store, analyze, and summarize the information, and notify the administrator or customer service personnel in a timely manner

The Problems of Online Monitoring Technology for Machine Tool IoT

-The interface protocols of machine tool equipment in the factory are complex and diverse. It is difficult to consolidate and upload directly to the upper computer server; We need an intelligent gateway device with multiple interfaces to collect and upload protocols.

-Many companies have outdated equipment and the cost of updating it is enormous. It is difficult to collect actual IoT data on existing devices.

-Data not only needs to be collected and analyzed locally, but also needs to be remotely transmitted and forwarded to the backend cloud server for remote monitoring and analysis, achieving IoT big data. So the device needs to support wireless 2G/3G/4G functionality.

-We need to provide a unified remote WEB function setting for easy function debugging, as well as a backend cloud server for data aggregation.

Solution

-Regarding the issue of scattered anomalies in monitoring points. The GEA-8401 gateway comes with a 7-mode 2G/3G/4G communication chip, which can wirelessly consolidate scattered data points into a data center or backend cloud server

-In response to the complex and diverse equipment and protocols involved in the factory, GEA-8401 supports commonly used protocols such as MODBUS internally, and can add non mainstream customized protocols through the direction of driver protocol addition. Customers can also add protocols themselves, and the actual data of different protocols can be summarized.

-For the old equipment in the factory, the parameters of the equipment can be collected through its own serial/network/analog/switch interfaces. Customers do not need to add any new data collection devices.

-We can provide users with mature backend cloud services, where customers can collect/accumulate/analyze data on the cloud platform and control/operate the cloud platform data through a mobile app, making it convenient for customers to maintain the condition of their devices.